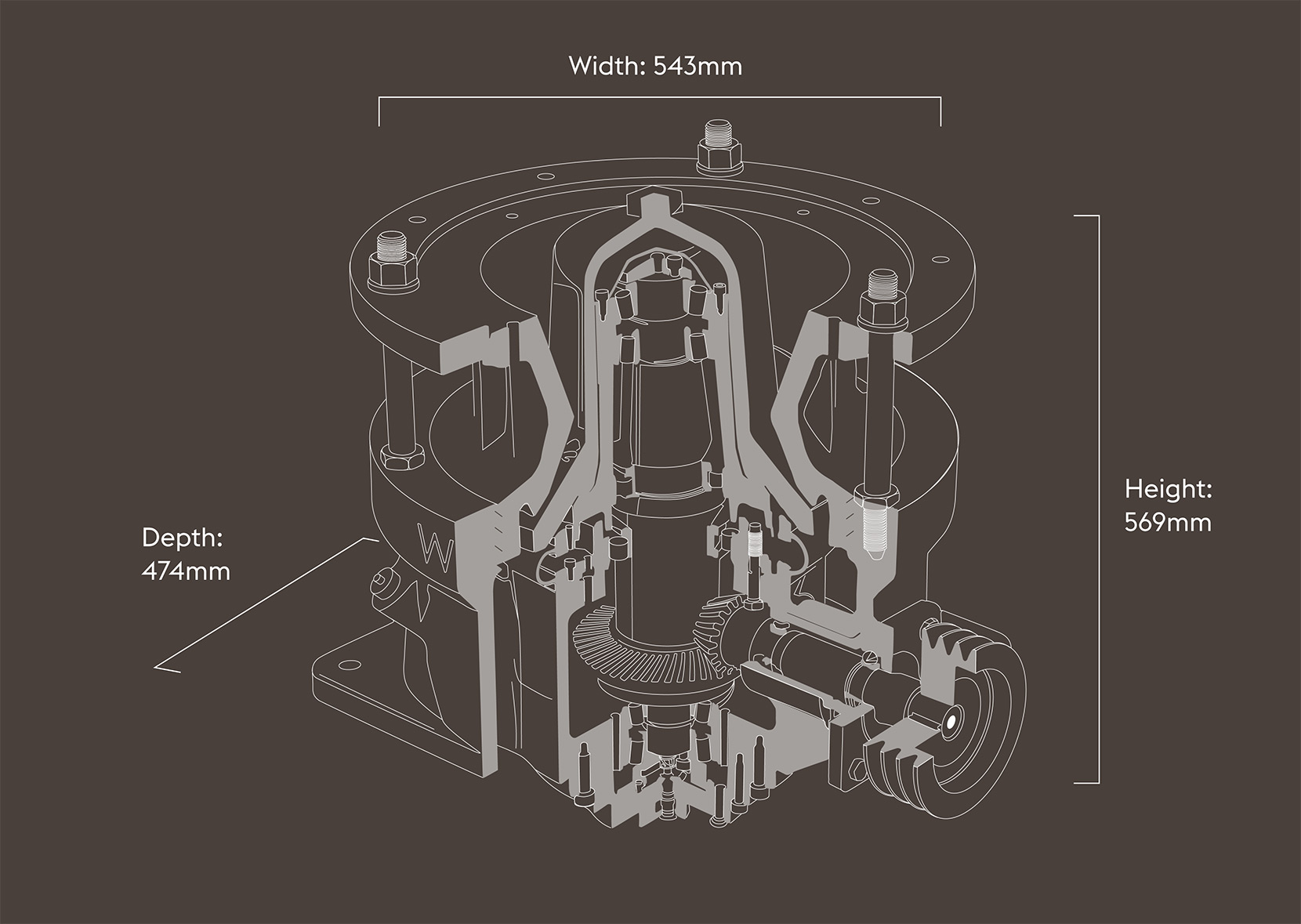

Wescone W300

The global sample crusher benchmark

See how they work

The Wescone Solution

1. High Throughput & Reduction Ratio

- Matches jaw crusher reduction ratios with high throughput performance

- Closed side setting adjustment 3-12mm

- Operating speed optimisation for fines adjustment

2. Build quality

- Over 20-years of research, development and life-cycle performance optimisation

- Australia's pre-eminent casting and component partners

- Quality control systems across material selection to assembly

- Benchmark ISO3082 accredited sample system crusher to global iron ore

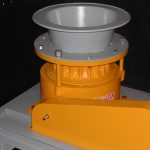

3. Wescone Crushing Action

- Double crush action for rapid reduction and oversize discharge mitigation

- Design optimises proximity of crushing action to crusher eccentric mass

- Operational imbalance minimised for increased operational speed

- High throughput with narrow discharge output specification

Assay lab testing

Wescone sample crushers are extensively integrated into mine site and industrial assay sample preparation and analysis systems across the globe. In particular, throughout the global iron ore industry in ISO accredited sampling systems and assay laboratory sample preparation.

Performance Capability

The Wescone crusher design delivers simplified laboratory sample preparation solutions. The Wescone facilitates:

- Reduced materials handling

- High single pass reduction ratio (up to 20:1)

- High throughput capability

- Rapid material reduction

- Discharge material size consistency.

Simplified Lab Design

The performance capability of the Wescone crusher provides for the potential to simplify laboratory design delivering:

- Reduced materials handling

- Improved preparation productivity & efficiency

- Accelerated sample preparation

- Reduced quality assurance risk.

Wescone Clients

Wescone W300s globally

Live map locating the W300 units in operation

Chat to our team about the Wescone W300

W300 series

in action

Why choose a Wescone?

Reduction Ratio Range

W300 reduction ratio range can achieve up to 20:1*

*subject to closed side setting adjustment

00:1

Throughput Capacity

Approximate throughput, materials dependent. Based on clean, dry, friable ore with a broken bulk density of 1.6 t/m3.

Sizing analysis - 6mm CSS

- Soft Ore

- Medium Ore

- Hard Ore

Versatility of crushable material

Materials routinely crushed by the W300:

- Iron Ore

- Bauxite

- Nickel ore

- Coal

- Manganese

- Gold ore

- Cement clinker

- Glass

Robust and reliable build quality

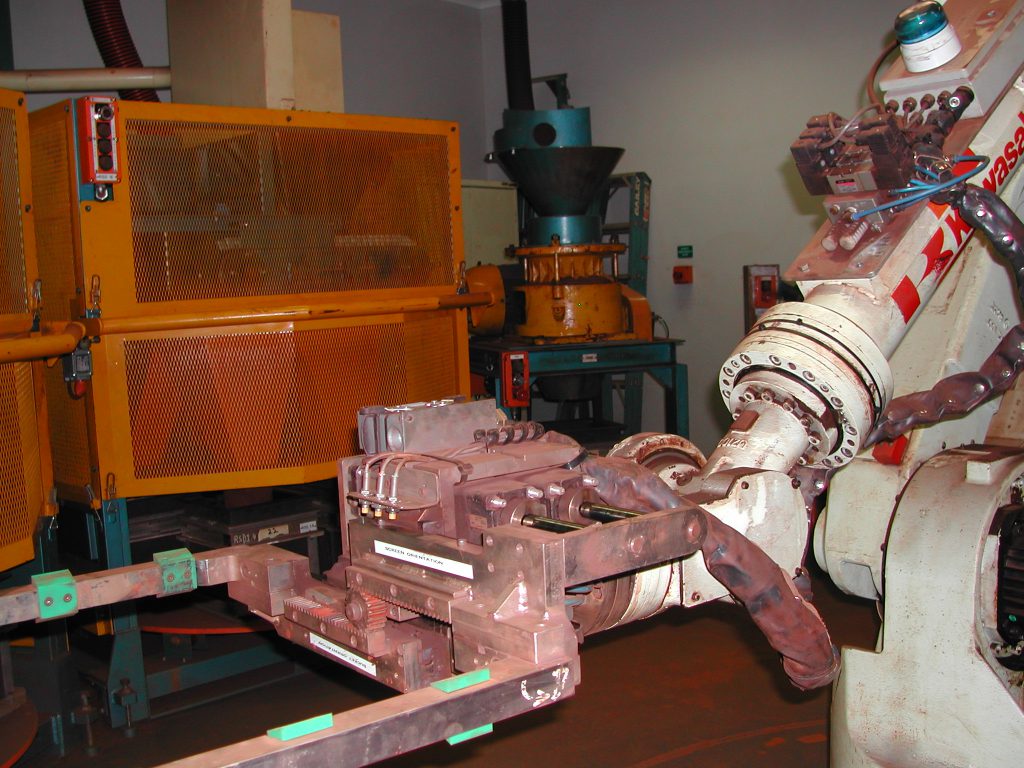

The Wescone W300 sample crusher is an integral component of numerous ISO3082 accredited sample preparation systems utilized in the global iron ore industry - a vital component of exported iron ore quality, grade and blending control.

The W300 has a proven track record, installed in robotic assay cell installations and in high duty mine site/port loading sample station locations. The Build Quality and internal oil lubrication system provides for extended life-cycle maintenance interval performance and simplified change-out completion.